Foam Injection

is ideal for complex structures, such as curves and spherical surface that are difficult to achieve while using the traditional thermos-molding, thermoforming or CNC processes.

DeCoto is divided into 4 types:

| Series | Description and Features |

|---|---|

Compression molding |

It is made from renewable raw materials and recycled PE resins which are made of recycled waste plastics. It not only has the characteristics of thermo-moldable and easy fabrication, but also can customize to meet specific customer needs. DeCoto is widely applied in various industries, ranging from personal protection and leisure activities to medical care products, and even day-to-day living applications. |

Double Expansion |

Extends the concept of DeCoto DE/DES foam, the DeCoto DUS foam comes with a much lighter density ranging from 0.04 to 0.05 g/cm3. The 2-Steps foaming process makes the foam lighter and is the choice for more industrial applications. The DeCoto DXS foam has a smooth and soft surface on the outside, and a uniform distribution of closed-cell structures on the inside which gives the DXS foam its excellent mechanical properties and stability, and it is non-toxic, odorless. |

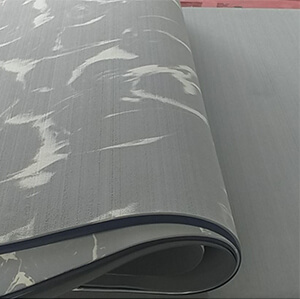

Physically cross linked |

It is widely used in a variety of applications. It can be used as a protector, as well as a protective and insulating foam layer for sound/heat insulation pads. |

Biobased Resins |

We uphold the concept of sustainable development, which is to protect the environment and reduce CO2 emission. DeCoto WB/WE Resins are emerging raw materials as sustainable alternatives for petrochemical EVA/PE. The methods of use are the same as that of common EVA/PE resins, so the number of particles can be flexibly adjusted in different manufacturing processes. |

2 recycling processes:

| Technology | Type | Description and Features |

|---|---|---|

Physical Recycle |

Compressed Remanufacturing |

Foam wastes are recycled for the grinding process to turn them into small particulates, and then compressed into recycled foam blocks and slabs. |

Chemical Recycle |

Compound Remanufacturing |

Contains up to 30% recycled foam residues, which were reprocessed into resins and added back into the compound to produce new recycled foam sheets. |

|

Recycle PE Resins |

Recycled PE resins are added to the foam production, and then compounded to produce a new foam. |

Nitrex has 3 series:

| Series | Description and Features |

|---|---|

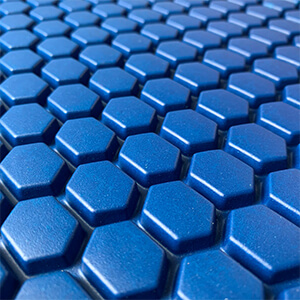

NX |

It not only maintains excellent impact protection performance, but also has high durability and comfort. The NX series are used in various protectors; including bicycle protection, equestrian equipment, and helmet liners. |

IX |

It has no PVC and can still maintain shocking absorption characteristics in low temperature environments. We have newly developed impact-resistant foam suitable for -20°C, which is lighter than PU foam and can easily meet safety standards and legal requirements. Therefore, the IX series is the best choice for winter protection. |

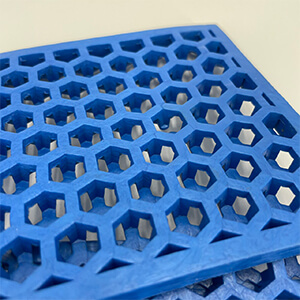

JX |

It is specially developed for the injection technology of hollow and 3D protections/ accessories. |

EVA GLORY is a company specializing in foam and providing integrated foam production solutions. Our R&D team focuses on material development, product design, prototyping and testing, the team takes innovative concepts into full-scale production, with a wild range of foam material for extreme sports protections, industrial applications, medical care, fitness and leisure industries, also shoe-making businesses. We ensure all new products and materials are extensively tested, evaluated and optimized at each stage during the development process ahead of client trials and mass production. EVA GLORY offers both ODM and OEM service, we are highly experienced with customization development projects with clients and fully understand the importance of each specific application needs.

we can also provide you with :

EVA GLORY is devoted to develop eco-friendly materials and create long-term sustainable practices that do more to respect the environment, the well-being of employees and the prospects of future generations.