We are looking for a long-term cooperative team.

Do you have innovative products, or would like to expand original products?

Drop us a line!

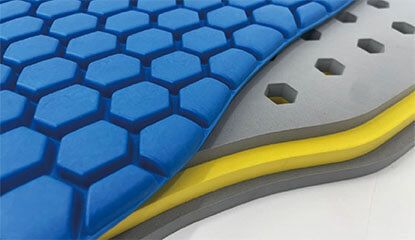

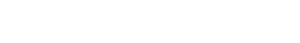

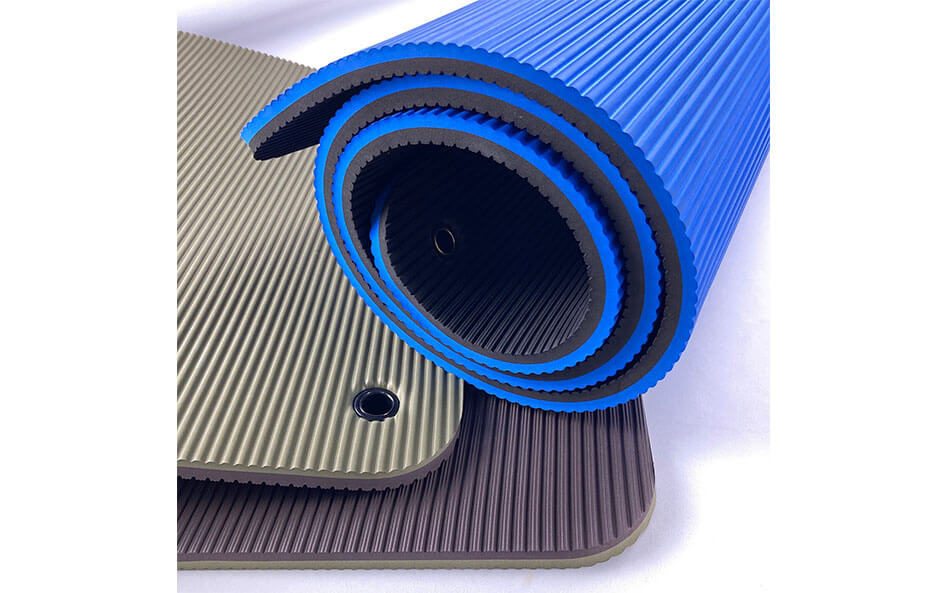

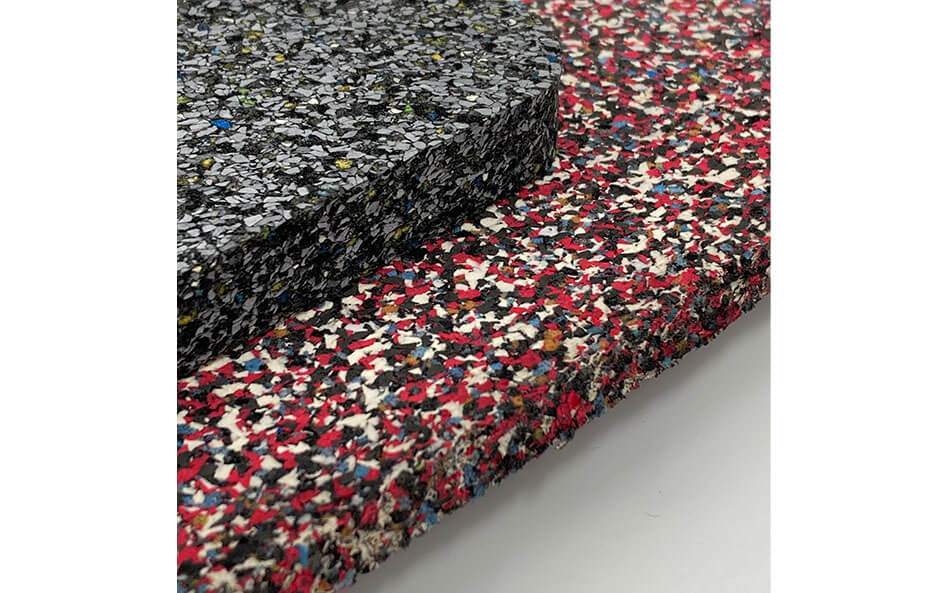

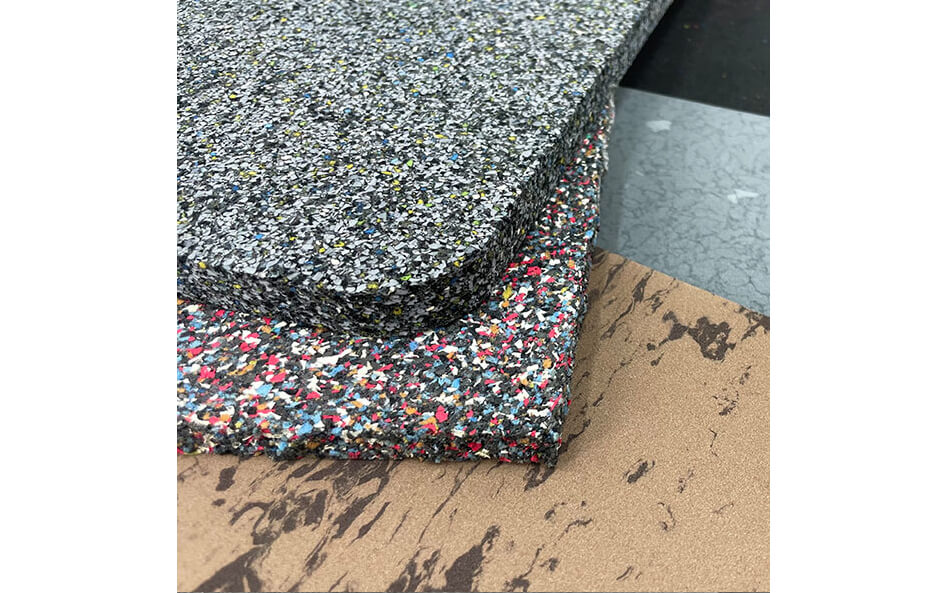

EVA GLORY provides our customers with a professional produce experiences and highly customized foam formulations. In addition to production through traditional manufacturing, we can also produce through foam injection technology to meet various needs of customers and enjoy high-quality services from development, technology to production.