Before engaging in outdoor activities, we need to think about how to treat and protect the global environment with which we are inextricably linked, find a symbiotic balance with nature, stop climate change and reduce natural disasters. EVA GLORY has developed foam materials that use renewable raw materials and reduce greenhouse gas (CO2) emissions: biobased foam DeCoto, and decreasing plastic, upgrading recycling: Recycle foam to reduce the impact on the planet.

EVA GLORY is a company specializing in foam and providing integrated foam production solutions. Our R&D team focuses on material development, product design, prototyping and testing, the team takes innovative concepts into full-scale production, with a wild range of foam material for extreme sports protections, industrial applications, medical care, fitness and leisure industries, also shoe-making businesses. We ensure all new products and materials are extensively tested, evaluated and optimized at each stage during the development process ahead of client trials and mass production. EVA GLORY offers both OEM and JDM service, we are highly experienced with customization development projects with clients and fully understand the importance of each specific application needs.

We can also provide you with

EVA GLORY is devoted to develop eco-friendly materials and create long-term sustainable practices that do more to respect the environment, the well-being of employees and the prospects of future generations.

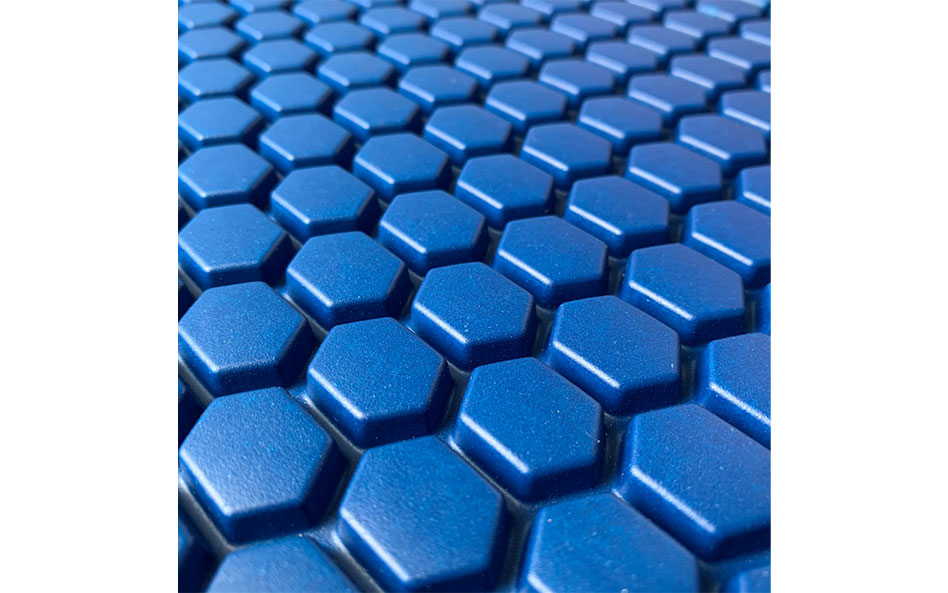

EVA GLORY has developed the faux teak foam material – Deva marine decking, which is made of durable, closed-cell PE/EVA foam. Deva is available in a variety of densities and colors shades and it offers an array of features with excellent characteristics such as: safety, comfort, noise reduction, UV resistance, shock absorption, anti-slip.

At the same time, Deva is a highly versatile material to work with: it can be easily processed by thermoforming, thermo-molding, and CNC processing. Deva’s surface can be further texturized by brushing or embossing to create unique carpet-like textures and patterns.

Marine activities – Marine deck (kayaks, pontoon boats, speedboats, wakeboard boats, yachts, fishing boats, etc), Boat protection pad, Ship fender, Poling and casting platform, Boat helm station pad.

Outdoor activities – Traction pad, Wetsuit, Paddleboard.

Indoor activities – Anti-slip surface at SPAs, pools, and indoor water sports activities, Swim platform mat.

EVA GLORY specializes in compounding foam materials to produce flexible, lightweight, durable foam materials that is UV-resistant, impact-resistant, and waterproof. We can provide a variety of specifications to meet different market applications, including mountaineering equipment,, camping gears, and riding accessories.

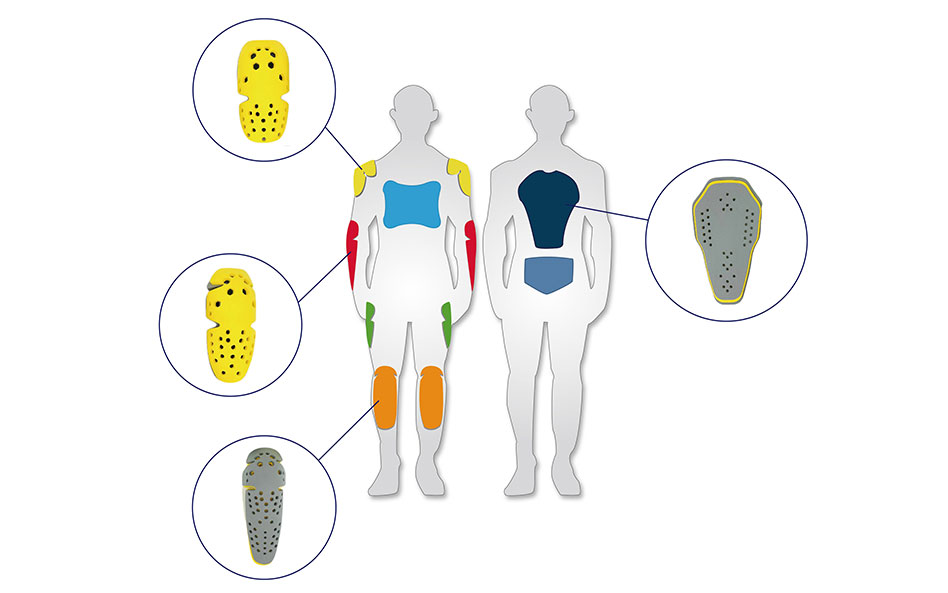

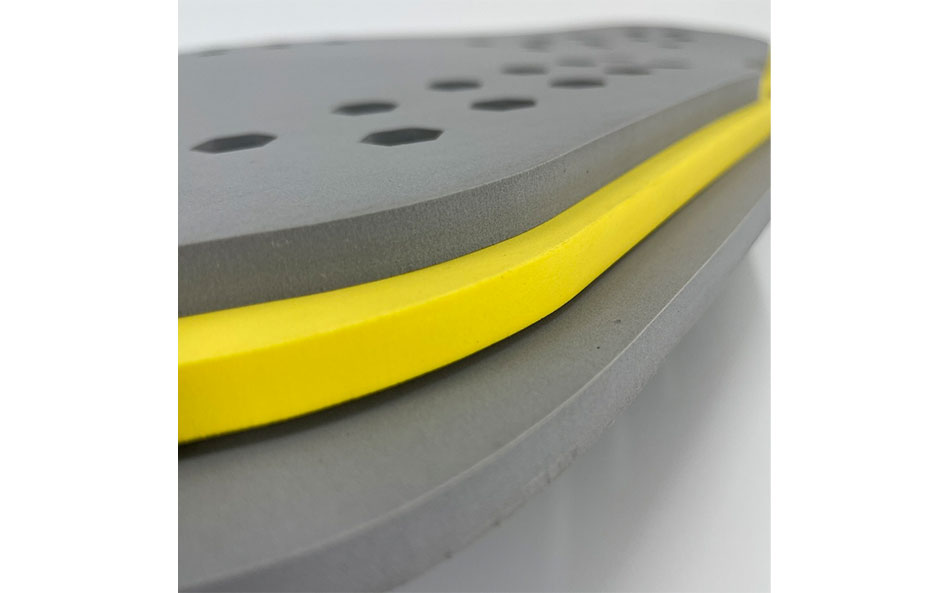

Our protection foam: Nitrex, with excellent shock absorption, impact resistance, can meet the performance requirements of EN1621 (motorcycle and winter sports) EN13158 (Equestrian) EN1077/1078 and NOCSAE for helmets protection standards. Nitrex is widely used as personal protective foam (such as knees, shoulders, limbs, back, head, chest, hips) to provide users with effective protection during high-speed movements or extreme activities.

In addition to traditional EVA foaming, EVA GLORY’s foam injection technology reduces material waste and can easily produce complex structures, curved surfaces, and achieve more ergonomic foam products.

Personal protection equipment – Winter sports (ski, skating, ice hockey), extreme activities (racing, BMX), Helmet liner.

Life and leisure – Injection-molded slippers, Injection molded knee cushion, Garden/Work kneeling pad.

Mountaineering and hiking – Trekking poles, Safety harness belt pad, Backpack padding.

Camping gears – Recreational vehicle mat, Cold/Warm storage bag, Camping tent mat, Insulation pad, Waterproof mat.

Bicycle accessories – Bike protection pads, Bike handlebar tape.

Sports activities – Volleyball kneepad, Racket grip tape, Baseball protector, Golf clubs, Equestrian sports (equestrian clothing, equestrian vests, saddle pads), horse accessories, baseball protector.

At EVA Glory, not only are we able to produce high quality closed cell foam to meet our customers’ requirements, we also have ability to recommend the best foam solution tailored to their needs.

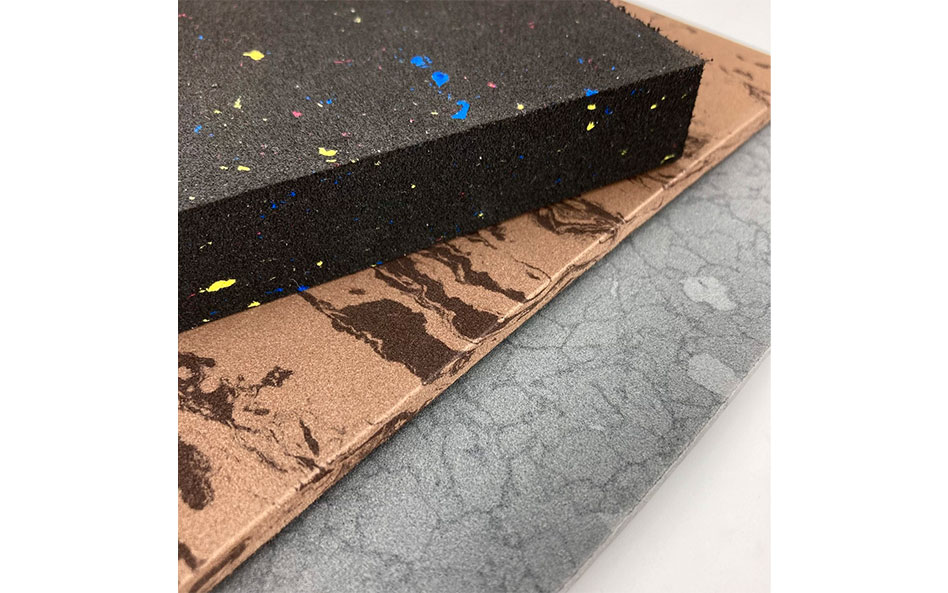

Moreover, we care deeply about the planet we live on. Therefore, we are committed to developing products that are in line with our philosophy of sustainable development and environmental protection. Over the years, we have successfully developed the biobased DeCoto foam materials that help reducing CO2 and greenhouse gas emissions by mitigating the use of petrochemical materials.

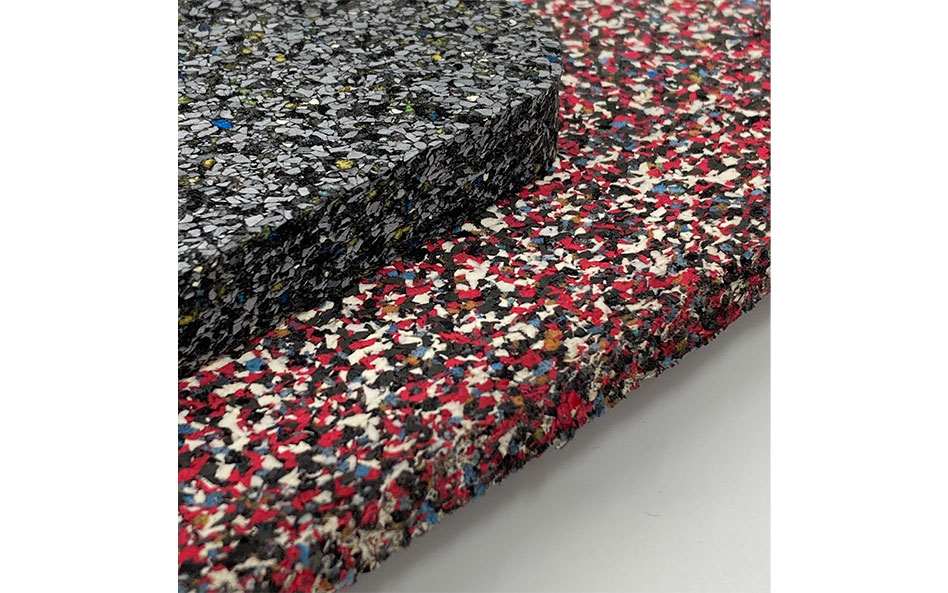

In addition to developing new materials, we also aim to achieve a sustainable, closed-loop production cycle by recycling plastic wastes to recreate EVA GLORY’s recycled foam material: Recycle foam.

The DeCoto foam and the Recycle foam are both highly versatile materials suitable for variety of production techniques such as compression molding, injection molding, lamination, CNC processing. As a result, they are widely applied in the production of fitness equipment, massage accessories, and various market applications.

Fitness equipment – (Folding) Yoga mat, Exercise mat, Aerobic mat, Yoga block, Yoga wheel.

Massage accessories – Foot massage mat, Massage roller, Massage ball

Other mat – Gym floor mat, Martial arts mat, Judo mat.

DeCoto is an eco-friendly biobased foam in which fossil EVA is replaced with biobased carbon. DeCoto is made from a wide range of renewable biobased feedstock including bamboo, rice husks, wood, agricultural waste, and recycled PE resins made of recycled waste plastic. DeCoto foam has the unique potential to reduce greenhouse gas emissions and it can be recycled at the end of its life cycle.

EVA GLORY focuses on the concept of sustainability. We change raw materials from their roots and actively recycle foam waste. At the same time, we’re committed to upcycling the recycled foam by enhancing its quality, application, and product life. We aim to realize the circular economy of foam products, creating a safe, harmless and balanced environment for mankind and the ecosystem.

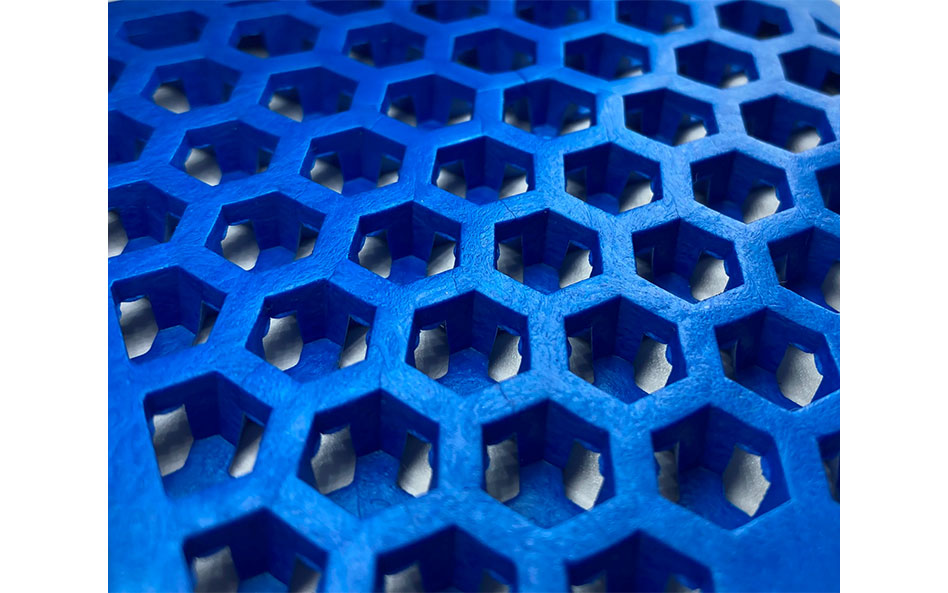

EVA GLORY develops protective foam materials for shock absorption and impact protection: Nitrex. It is used in extreme sports, motorcycles, industrial and military protection, as well as an anti-fatigue mats, cushioning pads, work/garden knee pads.

Nitrex is suitable for various processing techniques, such as thermo-molding and thermoforming. In addition, it can be cut and stitch like fabrics. Nitrex can be manufactured by injection molding to create hollow 3D structure parts for breathability and ergonomic design.