Foam Converting

Product Introduction

EVA GLORY is a professional foam manufacturer with extensive production experience and in-depth knowledge of foam materials. In addition to in-house capabilities, we collaborate with trusted machining partners to expand our processing capacity and support customers from product development to finished goods.

We offer a full range of foam converting services to meet diverse application needs, including foam cutting, foam molding, and custom finishing. See below for the key processing methods we provide.

Trimming

Cuts foam edges and shapes to size.

Splitting

Slices thick foam into thinner sheets.

Die-Cutting

Punches foam into custom shapes.

Thermal Lamination

Joins foam layers with heat and pressure.

Thermoforming

Heats and molds foam into curved or shaped forms.

Embossing

Adds patterns or textures on foam surface.

CNC Routing

Precision foam cutting and carving.

Laser Engraving

Etches brand logos or intricate designs.

Trimming

Vertical cutting for size adjustment

Trimming involves cutting the foam block vertically to adjust its length and width while keeping the original thickness unchanged. This process is used to create smooth, uniform edges or to cut the foam into strips and smaller blocks.

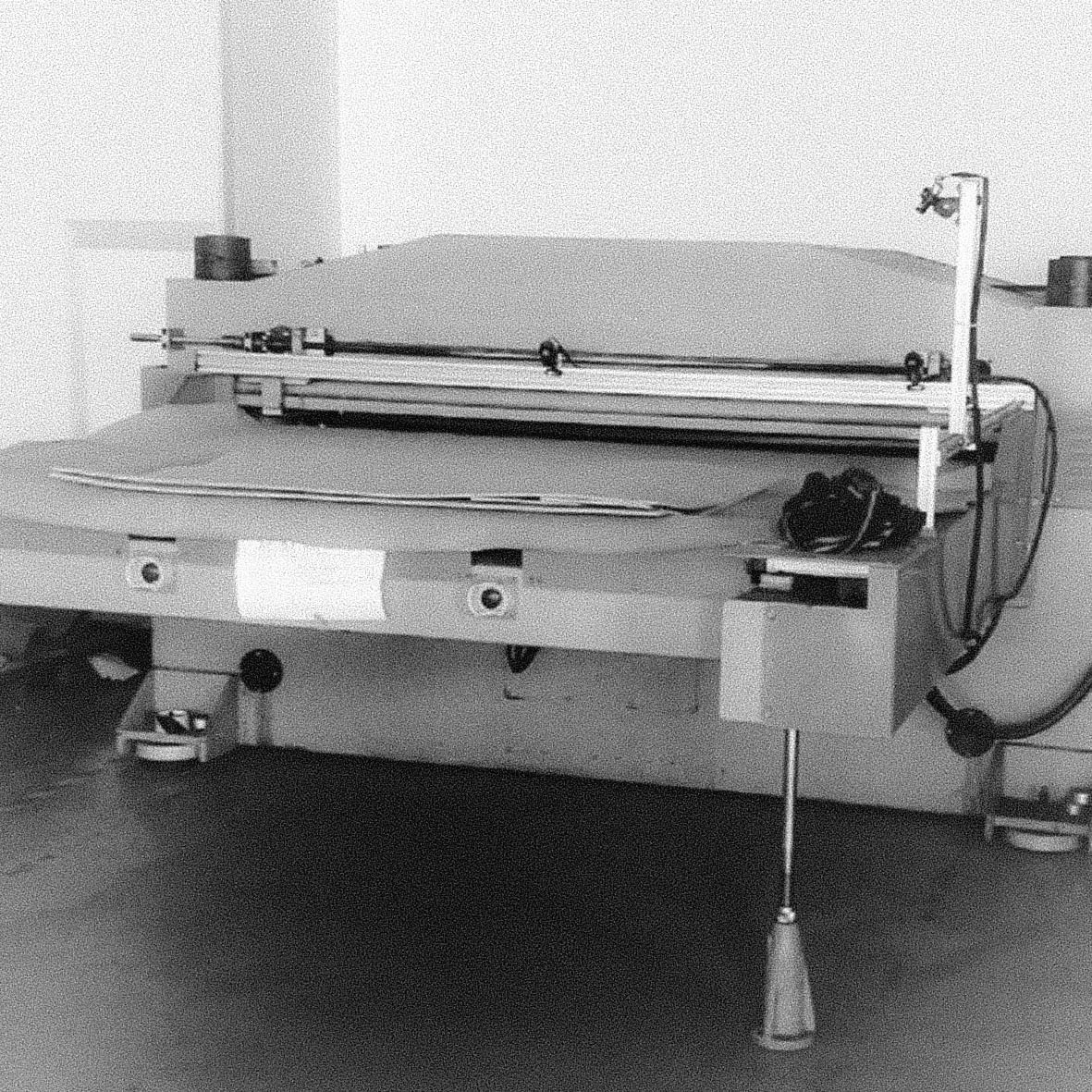

Splitting

Horizontal cutting for thickness adjustment

Splitting, also called “sheeting,” cuts the foam horizontally to reduce its thickness, producing sheets suitable for lamination or further processing.

Die-Cutting

Creating consistent shapes with precision cutting dies

Die cutting uses a die to punch foam into defined shapes – round, square, or custom. This process ensures consistent size and quality across batches, and it’s often used before assembling or forming the final product.

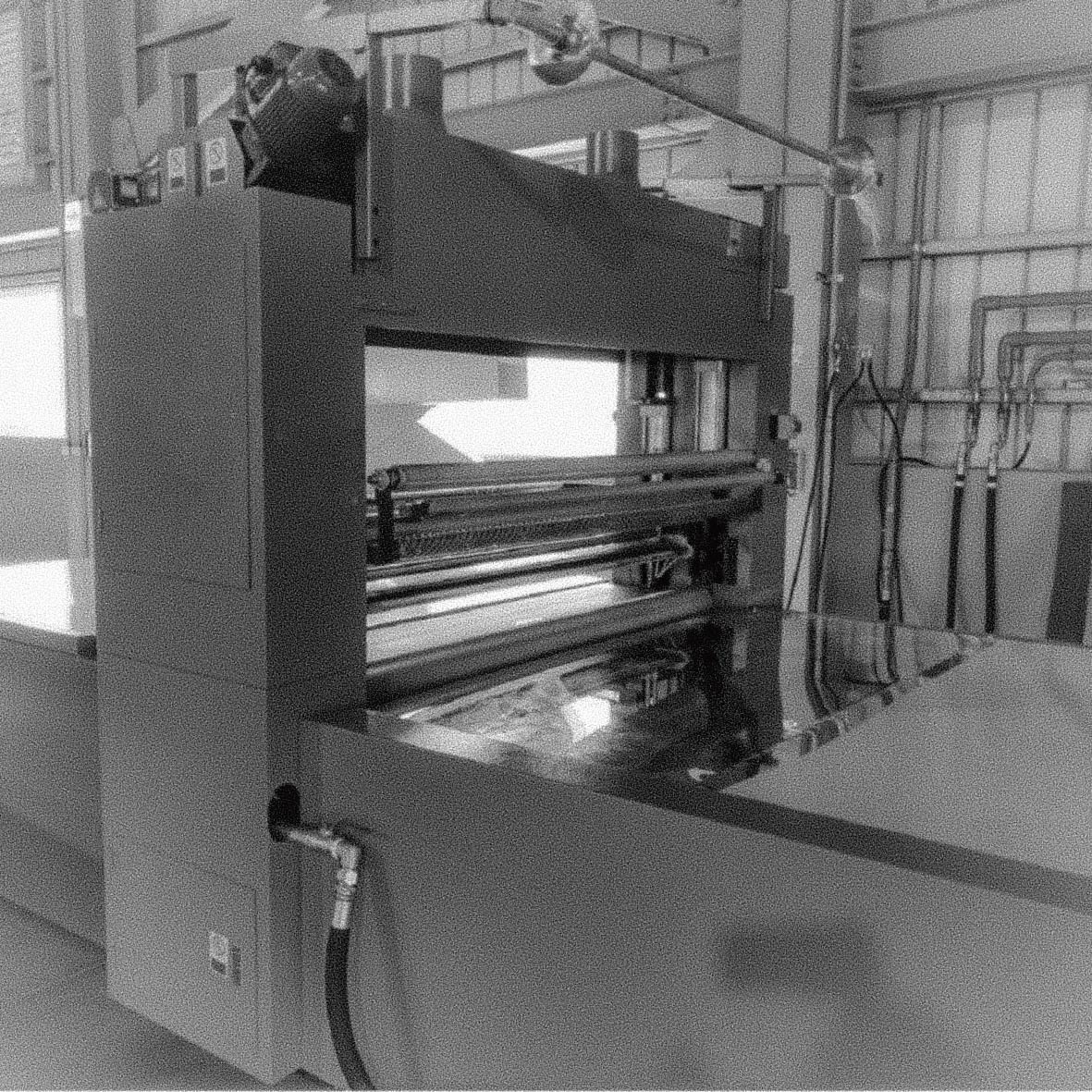

Thermal Lamination

Bonding foam layers without adhesive

Foam sheets are joined through heat and pressure using a heated roller system, creating a strong, uniform bond without adhesives. EVA GLORY’s JoinstickTM innovation takes this process further, delivering superior adhesion and long-lasting durability with 100% no-peel-off performance, making it ideal for marine decking and other demanding applications.

Relying solely on heat bonding without chemicals or additives, JoinstickTM eliminates glue odors and keeps workspaces cleaner. Its adhesive-free design also speeds up production, lowering labor and operational costs while ensuring durable, high-quality multi-layer foam products.

Thermoforming

Shaping with heat and molds

Thermoforming is a common foam molding process where the material is heated and formed using a mold. It’s used to create curved, contoured, or structured foam components – such as protective pads, packaging inserts, or custom-fit parts – where shape and strength are important.

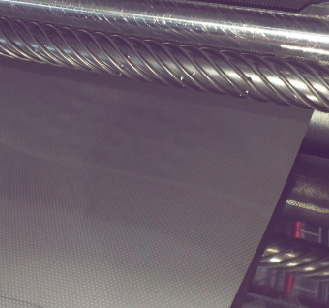

Embossing

Adding patterns or textures to the surface

Foam embossing creates visible patterns or textures on the surface. Depending on the foam’s characteristics, we use different methods to emboss defined square patterns or smooth curved lines, tailored to each customer’s design needs.

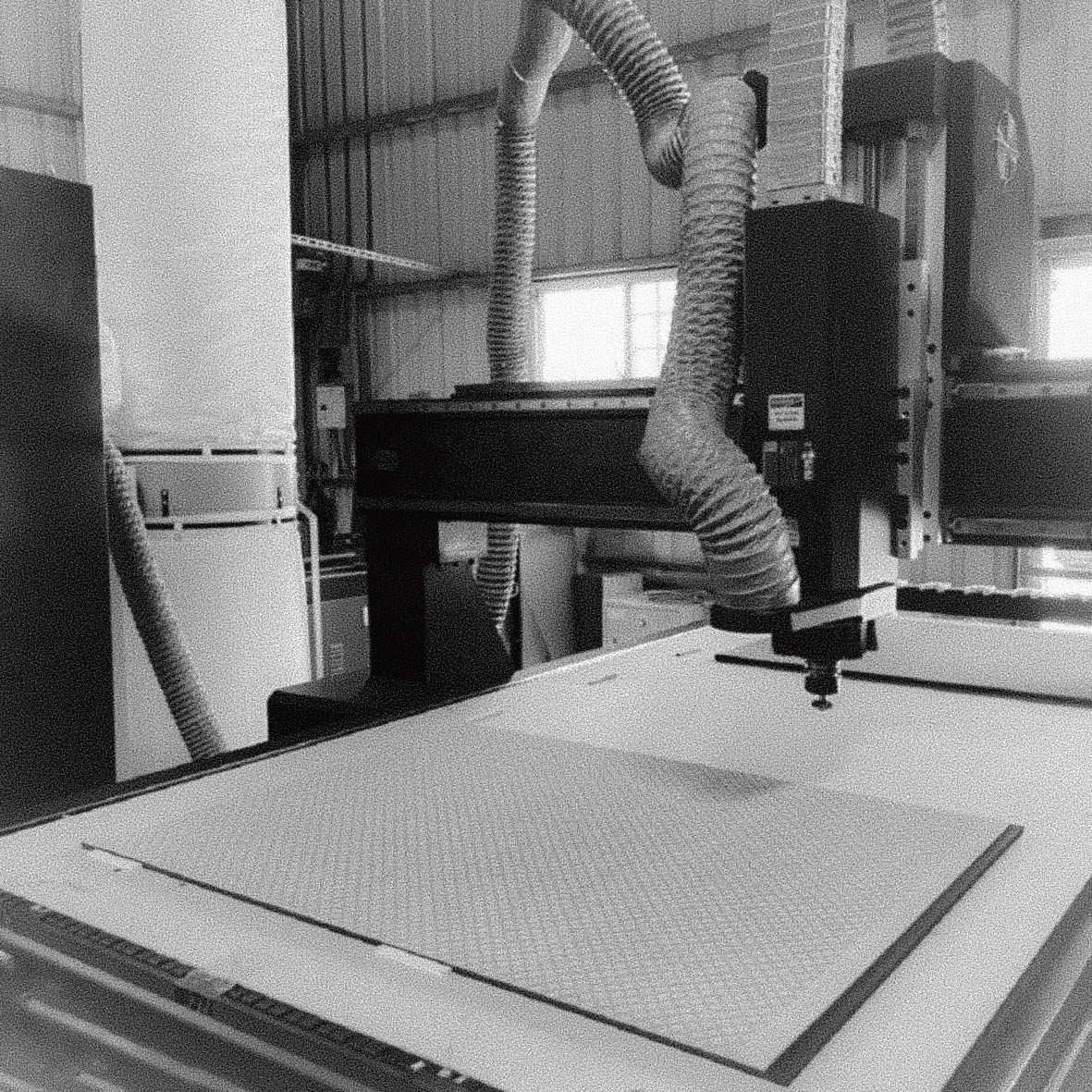

CNC Routing

Precision foam cutting and carving

CNC routing uses computer-controlled rotary tools to carve grooves, create channels, and produce 3D contours into foam blocks or sheets. This process is ideal for functional components, recessed features, and custom-shaped parts that require high accuracy and consistent replication of design files.

Laser Engraving

Etches brand logos or intricate designs

EVA GLORY’s laser engraving technology produces clean, permanent markings for logos, text, and decorative patterns. Our team carefully selects the right equipment and settings based on the foam’s physical properties, material characteristics, and color shade, ensuring every logo or pattern is sharp, clear, and uniquely customized.