Is EVA Foam Environmentally Friendly?

Is EVA Foam Environmentally Friendly?

In today's eco-conscious world, consumers are increasingly questioning the environmental impact of the materials they use. EVA foam, a versatile material found in everything from yoga mats and children's play tiles to athletic shoes and packaging, has gained popularity for its durability, flexibility, and cost-effectiveness. But as sustainability concerns grow, many are asking: Is EVA foam environmentally friendly? This article will explore what EVA foam is, its environmental impact, and ways to make it more sustainable.

What is EVA Foam?

EVA foam, or Ethylene-Vinyl Acetate foam, is a polymer material that combines ethylene and vinyl acetate to create a soft, flexible, and resilient product. Known for its rubber-like softness and elasticity, EVA foam has become ubiquitous in various industries due to its unique properties. The material is lightweight, waterproof, shock-absorbent, and resistant to cracking and UV radiation.

This versatile material appears in numerous everyday products, including:

- Athletic shoes and sports equipment

- Protective padding and cases

- Yoga mats and exercise equipment

- Children's toys and puzzle mats

- Craft materials and cosplay props

- Packaging and protective inserts

- Orthopedic supports and medical devices

Is EVA Foam Environmentally Friendly?

Traditional EVA foam, derived from petrochemicals, relies on non-renewable resources and contributes to carbon emissions. It is also non-biodegradable, meaning discarded foam can persist in landfills and fragment into microplastics, potentially polluting ecosystems.

To address these concerns, manufacturers are exploring eco-friendly alternatives, such as bio-based materials and renewable energy in production, to reduce reliance on fossil fuels and lower the environmental impact of EVA foam.

Ways to Make EVA Foam More Environmentally Friendly

As sustainability becomes a key focus, businesses are actively seeking ways to reduce the environmental impact of EVA foam. Instead of relying on traditional recycling, which is challenging due to contamination and mixed materials, manufacturers are adopting innovative approaches to make EVA foam more eco-friendly.

But before diving into these methods, it's important to understand why EVA foam is difficult to recycle in the first place.

Is EVA Foam Recyclable?

In most cases, recycling used EVA foam is difficult due to contamination and mixed material composition. Products often include adhesives, coatings, or other plastics that complicate separation and reprocessing. Additionally, used EVA foam may be dirty or degraded, making it unsuitable for high-quality reuse.

Because of these limitations, manufacturers are turning to more practical and sustainable solutions that focus on production efficiency and material innovation rather than post-consumer recycling.

Alternative Approaches to Sustainability

To reduce the environmental impact of EVA foam, companies are adopting upstream strategies that address waste and emissions at the source. Below are some key methods that are helping make EVA foam more environmentally friendly.

Recycling Production Waste

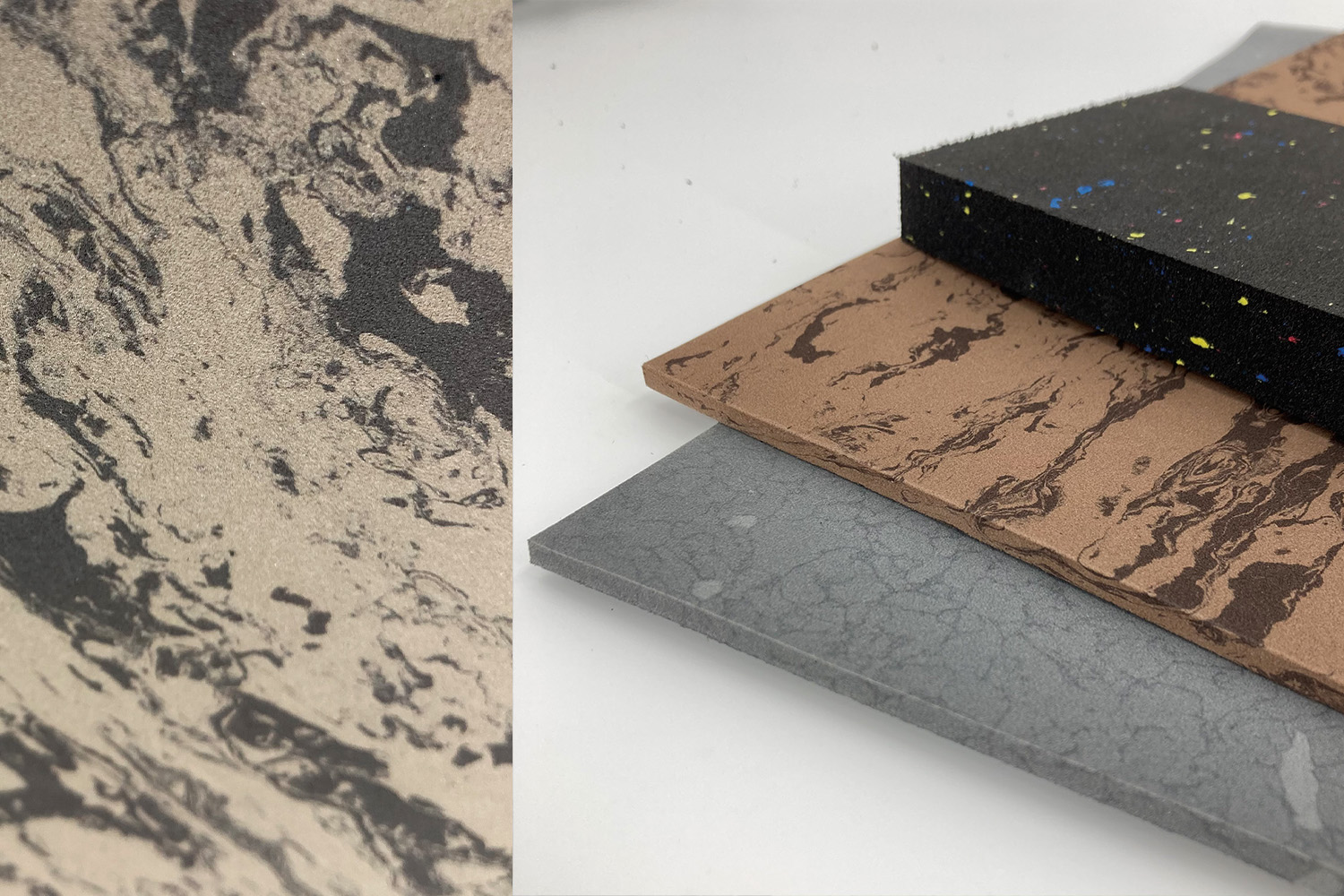

One effective way to minimize waste is by recycling residual materials—such as excess foam sheets, trimmings, and fabrication residues—directly within the production process. Instead of discarding these materials, manufacturers can blend them with new EVA to create fresh foam products.

Methods like composite remanufacturing and pellet regeneration allow these materials to be reintegrated into manufacturing without compromising product quality. This approach significantly reduces material waste, conserves resources, and improves overall production efficiency.

EVA GLORY has adopted this sustainable strategy by repurposing foam remnants and reintegrating them into its manufacturing cycle. By utilizing advanced recycling techniques, the company reduces waste and enhances material efficiency, contributing to a more sustainable EVA foam industry.

Incorporating Bio-Based Materials

To reduce reliance on fossil fuels, the EVA foam industry is increasingly turning to bio-based materials. By partially replacing petrochemical components with renewable resources—such as bamboo, rice husks, and agricultural waste—manufacturers can lower the environmental impact of EVA foam production.

These natural additives not only reduce the use of synthetic materials but also contribute to lower carbon emissions. Bio-based EVA retains the durability and flexibility of traditional EVA while offering a more sustainable alternative.

EVA GLORY has developed DeCO2 technology, which incorporates bio-based resources into EVA foam production. By integrating renewable materials like wood and plant-based fibers, the company creates foam products that support environmental sustainability while maintaining high performance.

Utilizing Sugarcane-Based EVA

Another eco-friendly approach is to produce bio-based EVA using ethanol derived from sugarcane. This biodegradable EVA foam provides a renewable alternative to traditional petrochemical-based foam while maintaining the same durability and flexibility. By replacing a portion of fossil-based ingredients with plant-based alternatives, sugarcane-derived EVA foam helps reduce carbon emissions and supports a more sustainable foam industry.

EVA GLORY has adopted this approach by integrating sugarcane-based EVA into its product lineup, further expanding its eco-friendly material solutions.

Green Manufacturing Process

Beyond material choices, optimizing the manufacturing process itself is crucial for minimizing EVA foam’s environmental footprint. Sustainable manufacturing practices include:

- Using renewable energy to power production lines.

- Implementing lean manufacturing to reduce material and energy waste.

- Choosing non-toxic foaming agents to eliminate harmful chemicals in production.

- Enhancing logistics efficiency to reduce transportation-related emissions.

Many manufacturers are investing in low-carbon technologies and adopting international environmental standards to ensure more sustainable production.

Since 2022, EVA GLORY has followed ISO 14064-1, implementing a greenhouse gas inventory system and transitioning to energy-efficient equipment. The company also prioritizes eco-friendly procurement by sourcing low-carbon materials and optimizing transportation routes to further reduce emissions. These initiatives demonstrate how green manufacturing practices can significantly lower the environmental impact of EVA foam production.

Redefines Sustainability

While traditional EVA foam presents environmental challenges, EVA GLORY is taking proactive steps to redefine sustainability in the foam industry. Through innovative material sourcing, waste reduction strategies, and internationally recognized certifications, EVA GLORY remains committed to reducing its environmental impact while delivering high-quality, durable products. These approaches allow the company to minimize its ecological footprint without compromising on performance standards.

In 2024, EVA GLORY earned Recycled Claim Standard (RCS) and Global Recycled Standard (GRS) certifications, ensuring traceability of recycled materials and compliance with ethical and environmental standards. With at least 5% recycled content under RCS and 20% under GRS, its products offer transparency and sustainability.

For businesses seeking eco-conscious foam solutions, EVA GLORY’s EVA foam delivers durability, performance, and sustainability. Choosing EVA GLORY supports a greener future while providing high-quality foam materials.