Recycled Foam

Product Introduction

Rethinking Recycled Foam

Plastic waste has become one of the world’s most urgent environmental challenges. While recycling is often seen as the solution, the reality is more complex. Many materials are difficult to recycle and often end up in landfills or are “downcycled” into lower-value products. Foam is no exception.

At EVA GLORY, we believe that recycled foam deserves a better path. By reusing production scraps and integrating bio-based materials, we turn foam into a more sustainable choice – without compromising on performance.

Closed-Loop Foam Recycling: From Waste to Resource

EVA GLORY adopts a closed-loop recycling system to convert manufacturing scraps into recycled foam materials. Instead of sending edge trims, offcuts, or sheet waste to landfill, these foam residues are collected and reused directly in production. This internal cycle reduces waste, conserves virgin resources, and supports a more sustainable manufacturing model.

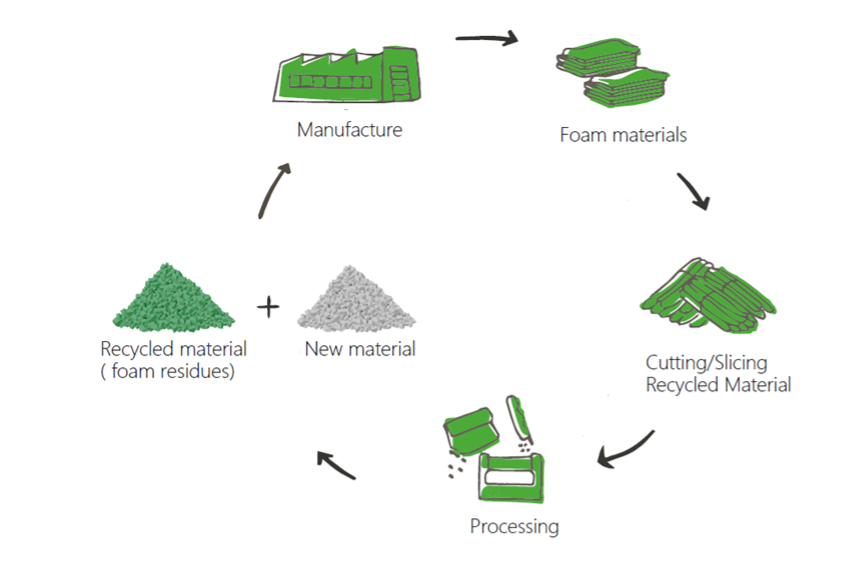

The diagram below illustrates how this loop functions:

After foam materials are fabricated into final products, leftover scraps are reclaimed and returned to the recycling line. These materials are then remanufactured into new foam compounds – closing the loop and minimizing overall material loss.

In practice, the reclaimed foam is ground and blended with virgin material to produce new foam sheets with up to 30% recycled content while maintaining consistent product quality. This step keeps valuable materials in circulation and reflects EVA GLORY’s commitment to responsible, recycled foam manufacturing.

Certifications & Traceability

EVA GLORY ensures the integrity and traceability of its recycled materials through internationally recognized certifications:

RCS (Recycled Claim Standard)

Products contain at least 5% verified recycled content.

GRS (Global Recycled Standard)

Products contain at least 20% recycled content and comply with environmental and social responsibility standards throughout the supply chain.

These certifications offer transparency and assurance to clients seeking eco-conscious recycled foam materials.

Other Eco-Friendly Practices

Beyond recycled foam, EVA GLORY reduces environmental impact by:

- Using bio-based additives like bamboo and rice husks to cut fossil material use

- Incorporating sugarcane-based EVA as a renewable alternative

- Following green manufacturing standards such as ISO 14064-1

These methods support a more sustainable approach across the entire production process.

Let’s Build a More Sustainable Future

Whether you’re looking for recycled foam solutions or ways to incorporate sustainable materials into your product line, EVA GLORY is ready to help. Our foam products combine performance with a lower environmental footprint – and we’re always open to co-developing new eco-friendly applications.

Contact us to explore how our materials can support your sustainability goals.