EVA/PE

Product Introduction

Excellent EVA/PE Foam Blends

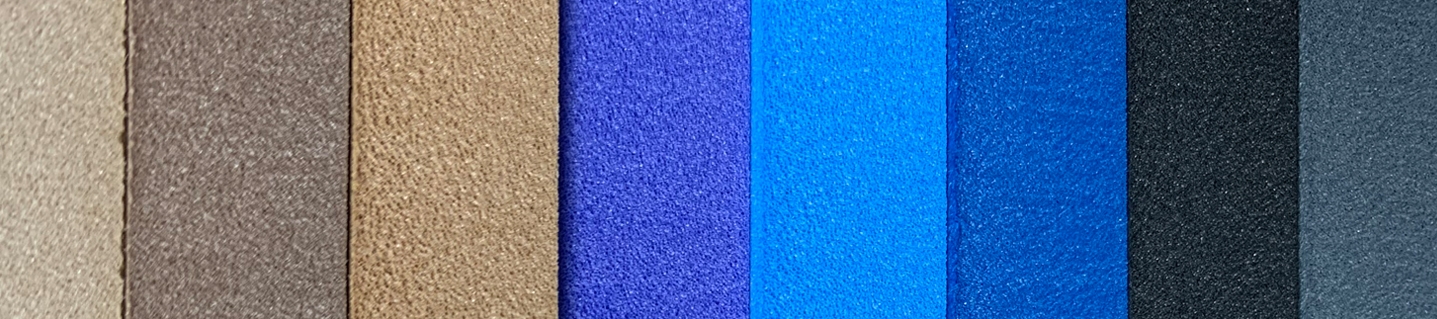

As an experienced PE and EVA foam supplier, we draw on the strengths of both materials to create hundreds of compound formulations. We customize our foams across density, hardness, and rebound – from soft, flexible grades to durable, high-density EVA FOAM blends and from highly elastic to inert performance. This versatility enables us to deliver solutions tailored for industries including marine, automotive, sports, footwear, healthcare, and more.

Closed-Cell Structure: Core Benefits

EVA/PE foam features a closed-cell structure, where each air pocket is fully sealed to form a continuous, non-porous material. This structure provides key functional advantages:

Water Resistance

Sealed cells block liquid penetration, keeping the foam dry even under direct exposure.

Buoyancy

Trapped gas within the cells lowers the foam’s overall density, giving it sustained flotation without water absorption.

Air & Vapor Barrier

The continuous, impermeable structure blocks air and moisture, maintaining sealed, dry environments.

Thermal Insulation (-40°C to 90°C)

Air pockets slow heat transfer, providing moderate insulation within this range.

Key Features

Shock Absorption & Rebound

The elastic, closed-cell structure absorbs impact and returns to shape, providing reliable cushioning.

UV & Weather Stability

Resistant to UV, the foam remains flexible and avoids brittleness or discoloration under sun exposure.

Chemical & Moisture Stability

The foams resist oils, solvents, mild acids/alkalis, and moisture – ideal for industrial and marine environments.

Noise & Vibration Dampening

EVA/PE foam absorbs vibration energy and moderately reduces mid-high frequency noise, aiding resonance control.

Safe and Compliant

The foams are regularly tested for REACH compliance, confirming they do not contain any Substances of Very High Concern (SVHC) above permitted levels. This ensures protection for both human health and the environment, making them well-suited for use in medical, consumer, and other sensitive applications.

Applications

-

Marine & Outdoor

Floating gear, marine decking, waterproof cases -

Sports & Leisure

Yoga mats, gym flooring, massage rollers, protective sports gear -

Protective Gear

Knee/elbow pads, helmet liners, motorcycle guards -

Footwear & Orthotics

Custom midsoles, insoles, heel stabilizers, orthopedic foot supports, prosthetic support -

Medical & Healthcare

CNC-milled EVA blocks for custom therapeutic cushions and prosthetics -

Industrial & Packaging

Gaskets, carwash strips, protective packaging inserts, machine pads -

Home & Hobby

Cosplay props, pet mats, sound-damping panels

Customization Options

- Hardness (Durometer): Asker C 10-85 (butt-joint rolls ≤ 50 C); Shore 00: 35-90; Shore A: 5-70 (typical flexible elastomers)

- Density: 0.05-0.50 g/cm3 (3-31 lbs/ft3)

- Thickness: 1-100mm (dependent on compound)

- Formats & Sizes: Sheets (1-2.5m2) or rolls; flat-lay packaging

- Surface & Appearance: Custom colors, textures, embossing, printing

- Additives: Flame-retardant, anti-static/ESD, UV stabilized, adhesive backing, multilayer lamination

Processing Methods

EVA/PE foams can be precisely shaped and enhanced through: Splitting/skiving, die-cutting & CNC routing, lamination, thermoforming, and bonding – facilitating seamless integration into end-use applications.

Ready to customize your EVA/PE solution? Contact us today!